Embellishment

We don’t simply supply blanks. We provide garments ready to brand or embellish with your logo or other branding. The difference is in the materials and design. All Cloke garments have been crafted to create a canvas that’s designed to be embellished. They’re designed to take either screenprints, transfers, embroidery or other embellishment methods. They’re designed to look good and last. You might not see the immediate difference when you open a box of Cloke garments...but you’ll see it when you brand them.

Here are the main embellishment techniques, and their pros and cons:

Screenprinting

Great for big, bold and beautiful graphics on hoodies and tees. Also known as silk screen printing. Artwork can usually be up to 30cm wide by 35cm high, and in some cases bigger – check with your screenprinter for their capabilities. Very cost effective for volume production – e.g. 20+ garments, but not suited to small runs due to setup costs. Some printers have automatic carousels which are perfect for jobs of 1000+ units.

Technical

Garments with a polyester content need more care at the high temperatures associated with screenprinting and transfers. If overheated, dye from the polyester can ‘migrate’ into the ink. This can appear up to 5 days after the ink is cured.

Overheating can occur because temperatures are set too high, but also because of heat buildup – your gear will be hotter at the end of a run than the start. And as the garments absorb heat, they can be hotter than the temperature gauge your dryer indicates.

To ensure garments are not overheated, particularly garments with polyester content, print with a low bleed and blocker-based inks. Use no more heat than necessary to cure the ink; max 160 degrees C. Look out for marle coloured garments that have polyester or viscose added.

Embroidery

Great for smaller logos, especially on jackets. As the embroidery thread is stitched through the fabric, it will last the lifetime of the garment – there is no possibility of it washing of. This physical stitching makes for a very classy looking logo, however it is not suited for fine detail. Ask your embroiderer to mock-up (digitize) your design so you can see what your artwork will look like when converted to stitches.

Vinyl Transfers

Vinyl transfers are machine cut from a special type of vinyl, then heat-pressed on to the garment. Often used for individual names (think school leavers) team numbers, and hi-viz. Speciality vinyls are also available – glow in the dark, glitter, etc.

Technical

For any garments containing polyester, including hoodies, jackets and performance wear, use blocker transfers to avoid dye migration. Do not overheat/over-press.

Direct to garment (DTG)

DTG printers are like an inkjet for fabric. DTG prints work particularly well on cotton tees. Complex designs such as photo prints are possible, which are not practical with screenprinting. The finished print feels soft and breathable. Setup costs are minimal which makes DTG great for small quantities. For larger quantities, cost per garment is usually higher than screenprinting.

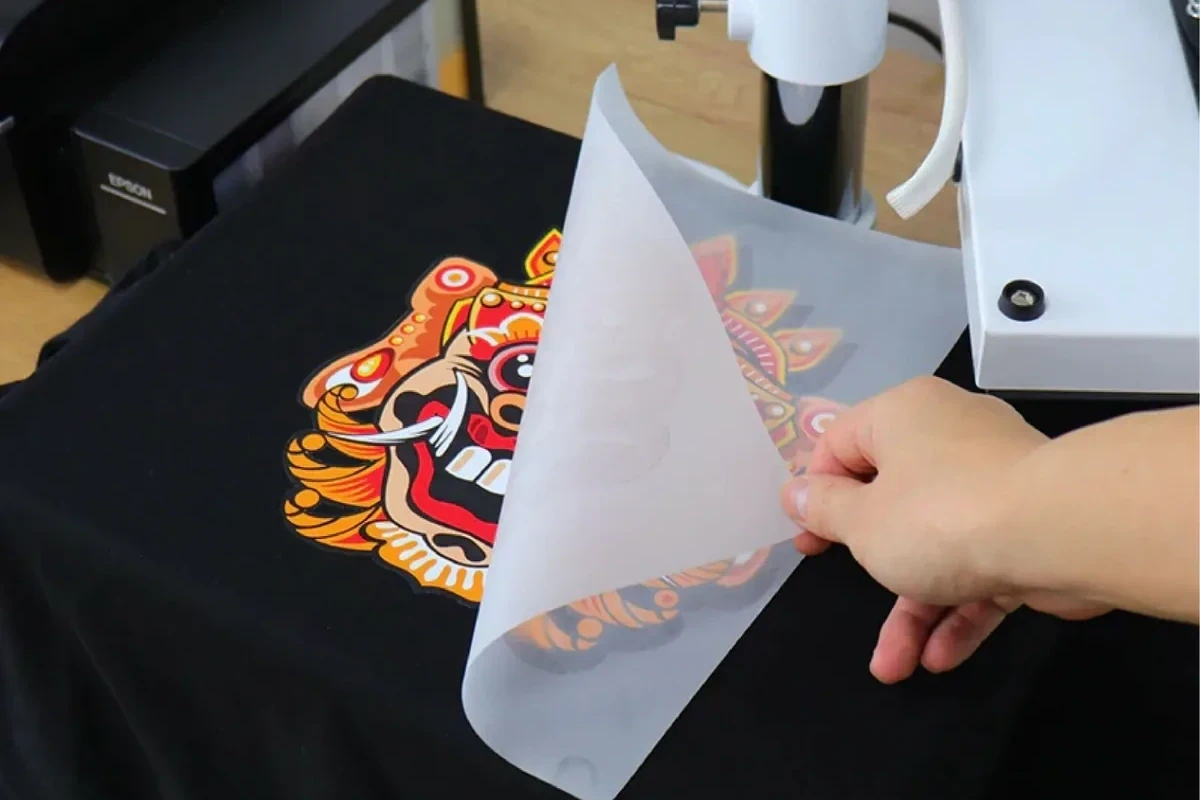

Direct To Film (DTF)

DTF involves printing onto a special film, which is then fused to the garment with a heat press. Complex, multiple colour designs are possible, and special films are available for printing on to fabrics that do not suit other print/heat techniques. The finished print is thicker than DTG and not breathable.

Technical

For any garments containing polyester, including hoodies, jackets and performance wear, use blocker transfers to avoid dye migration. Do not overheat/over-press.

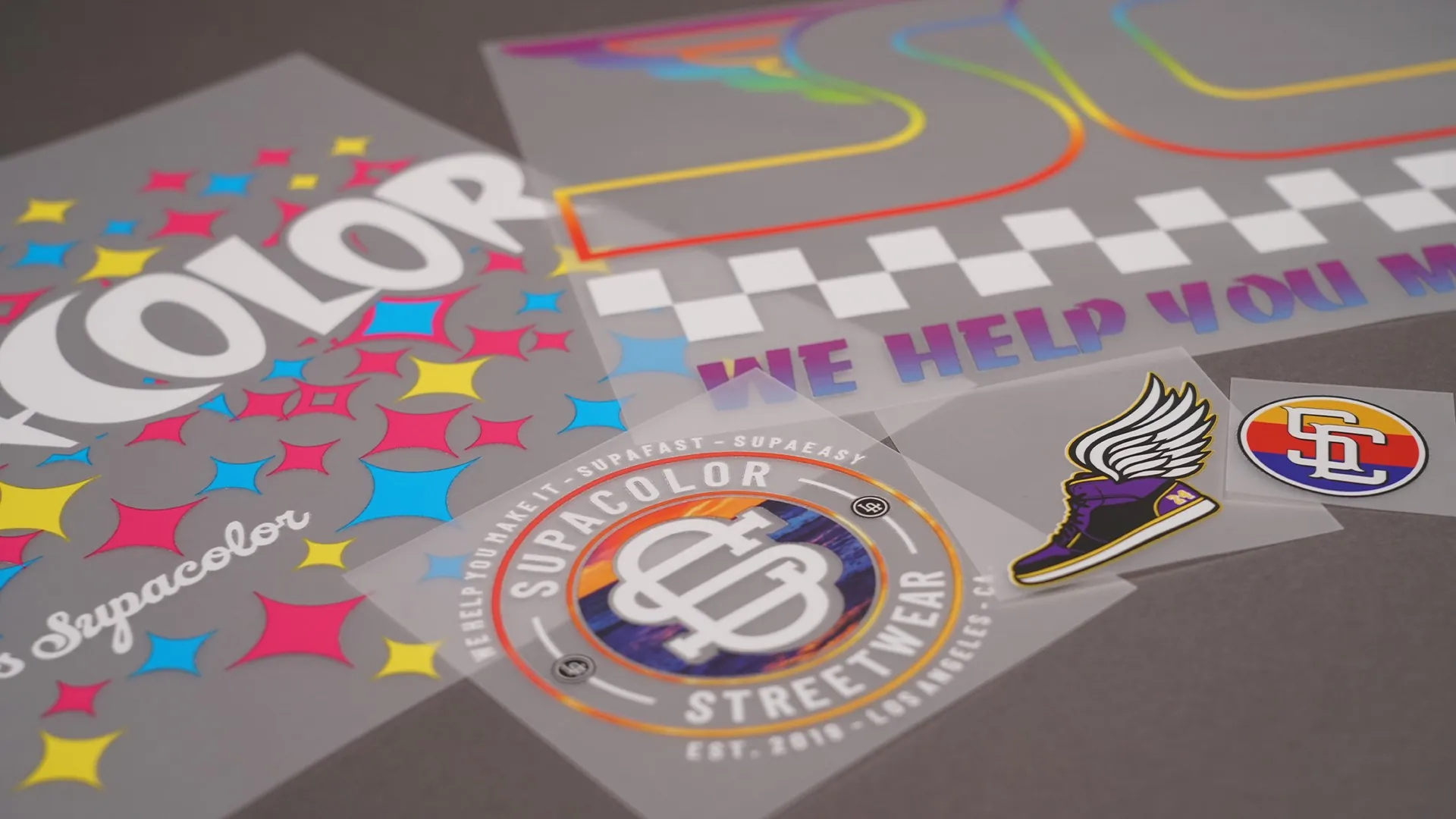

Supacolour.

Supacolour make custom heat transfers for every situation, including transfers for garments that are usually not suited to transfers or printing such as softshells, performance fabrics, etc.

Read more on their website.

Explore our fabric profiles or check out our range of apparel ready for you to make your mark.